More Rope Suppliers

History of Rope

The origins of rope are both ancient and fascinating, with archaeological findings indicating that rope-making dates back over 28,000 years in Europe. Impressions of cordage were discovered on pit-fired pottery, marking some of the earliest evidence of rope technology. A remarkable discovery in the Lascaux Cave in France revealed fossilized fragments of two-ply rope, roughly 7 mm in diameter, believed to date to around 15,000 BC. Early rope was crafted by prehistoric people who hand-twisted and braided plant materials such as grass, reeds, and vines, laying the foundation for the evolution of modern rope manufacturing.

Moving forward in history, the ancient Egyptians were pioneers in transforming ropemaking into a specialized craft between 4000 and 3500 BC. Utilizing ingenious tools—often weighted wooden objects tied to sticks—they twisted fibers into strands and combined those strands to form rope. The Badarian culture of Upper Egypt initially relied on water reed fibers, but over time, the Egyptians diversified their materials, incorporating date palm, papyrus, rushes, wild reeds, halfa grass, esparto grass, and flax. Occasionally, animal fibers such as camel hair or leather were used for specific applications. Rope played a crucial role in Egyptian society, notably in moving massive stones for monument construction and supporting large-scale architectural projects.

In Asia, the ancient Chinese made a significant contribution to rope technology by popularizing hemp rope around 2800 BC—a practice that would become influential across continents. By approximately 1000 AD, indigenous peoples of the American Southwest independently developed similar ropemaking techniques, adapting materials and methods to their environments and needs.

Throughout the Middle Ages, rope served as an essential tool across Europe, though the intricacies of its manufacture remained closely guarded secrets among guilds. Artistic depictions from as early as 1393 suggest that ropemaking began with spinning yarns—a process fundamental to the creation of strong, stable cordage. Ropes enabled the construction of bridges, the operation of ropewalks, and the expansion of maritime trade. Sailors and merchants, in particular, advanced the art of splicing ropes, which became a vital skill in ensuring the safety and efficiency of seafaring ventures.

Technological innovation accelerated during the Industrial Revolution. In 1792, British inventor Edmund Cartwright introduced the Cordelier, a groundbreaking ropemaking machine. This invention marked the beginning of mechanized rope production and inspired a wave of similar advancements, making rope more accessible and consistent in quality for a growing number of uses.

Today, rope remains a cornerstone of modern industry and daily life, though the materials have evolved significantly. While natural fibers are still valued for certain applications, synthetic rope materials—introduced in the 1950s—now dominate due to their superior durability, strength, and resistance to rot, corrosion, and UV damage. Modern ropes are engineered to be both stronger and lighter, supporting a wide array of industries, from construction and marine transport to outdoor recreation and emergency rescue. If you’re interested in the evolution of rope technology and its modern applications, explore our guides on synthetic rope and natural fiber rope.

Rope Design

Materials

Today’s rope suppliers use a broad spectrum of materials to address an ever-expanding range of applications. Leading manufacturers produce ropes from synthetic fibers such as nylon, polyethylene, polyester, polypropylene, and high-performance materials like Kevlar and Spectra. These synthetic materials are celebrated for their flexibility, tensile strength, low stretch, and superior resistance to abrasion, chemicals, and environmental exposure. As a result, they are frequently specified for demanding uses in marine, industrial, and safety applications.

On the other hand, natural fiber ropes—crafted from materials like sisal, jute, manila, linen, coir, and cotton—continue to hold a place of distinction in applications requiring biodegradability, a natural appearance, or a softer hand feel. For instance, manila rope is prized for its superior strength and durability in marine and landscaping projects, while cotton rope is favored for crafts, animal handling, and decorative uses due to its softness and pliability.

Some applications require even greater strength and durability, leading to the production of wire rope made from metal alloys such as stainless steel or galvanized steel. These metal wire ropes are essential in heavy lifting, construction, rigging, winching, and hoisting, offering exceptional load-bearing capacity and resistance to abrasion and corrosion. This wide array of materials allows rope suppliers to tailor rope products to the unique requirements of industries such as shipping, construction, mining, arboriculture, agriculture, entertainment, and public safety.

Are you looking for a rope material that matches your project’s requirements? Contact a rope supplier to discuss your application and receive expert recommendations.

Construction

Rope construction is another critical factor influencing performance, safety, and suitability for different tasks. The two main techniques used in rope manufacturing are twisting (also known as laid rope) and braiding. Twisted rope, the more traditional method, involves coiling three or more fibers or strands together in the same direction, creating a helical structure. The fibers themselves are twisted in the opposite direction, a process known as counter-twisting, which imparts balance and helps prevent kinking—a crucial feature for climbing, rigging, and other safety-critical applications.

Braided rope, by contrast, involves weaving multiple strands together in intricate patterns. This technique produces ropes that maintain their shape and resist spinning or unraveling under tension. Several styles of braided rope are available, including:

- Diamond braid with a core: Features a solid inner core for enhanced strength and reduced stretch, ideal for load-bearing tasks.

- Hollow diamond braid: Constructed by weaving strands over and under each other with no core, providing flexibility and ease of splicing, often used for marine or utility ropes.

- Solid braid: Lock-stitched and tightly woven, these ropes resist unraveling and are suitable for applications requiring consistent diameter and strength.

- Double braided: Comprises a braided core within a braided sheath, offering the highest strength, flexibility, and resistance to abrasion; often used in marine, rigging, and rescue operations.

It’s important to note that some braided ropes, such as those with solid braid or core, cannot be spliced—a critical consideration for users requiring custom lengths or terminations.

Wire rope construction is even more specialized, involving multiple strands of metal wire twisted into a helix, then grouped into larger cables. This design maximizes both flexibility and load capacity, making wire rope indispensable for cranes, elevators, bridges, and industrial hoisting systems.

Types of Rope

The rope industry offers an impressive selection of rope types, each engineered for specific uses and environments. Here’s an in-depth look at the most common types and their typical applications:

Nylon rope is widely regarded for its superior elasticity, excellent shock absorption, high tensile strength, and remarkable longevity. Thanks to its resistance to weathering, chemicals, UV rays, and abrasion, nylon rope is a preferred solution for demanding applications such as towing, hoisting, lifting, anchor lines, dock lines, and safety harnesses. Its ability to stretch under load makes it especially suitable for dynamic loads, reducing the impact on connected systems and ensuring safety in critical operations. Learn more about nylon rope suppliers and evaluate options for your next heavy-duty project.

Polyester rope offers excellent resistance to abrasion, UV rays, and chemicals, combined with low stretch and high strength. Although less elastic than nylon, polyester rope is renowned for its durability in harsh outdoor and marine environments. It is commonly chosen for sailboat rigging, mooring lines, anchoring, tree work, and any application where exposure to sun and saltwater would degrade lesser materials. Its longevity and reliability make it a favorite among boating professionals and arborists alike.

Polypropylene rope stands out as the only synthetic rope that floats, making it ideal for water sports, pool lines, light mooring, and rescue throw bags. Its low density and bright colors enhance visibility and utility in aquatic environments. However, polypropylene rope has a lower melting point and limited UV resistance, so it is best reserved for light-duty or temporary outdoor use where cost and floating capability are key deciding factors.

Polyethylene rope is another floating synthetic option prized for its outstanding abrasion resistance and durability. It is widely used in commercial fishing, aquaculture, and marine transport due to its ability to withstand tough conditions while remaining buoyant. Polyethylene rope is also favored for netting, crab lines, and environmental containment booms, where abrasion and water exposure are major concerns.

Sisal rope, made from the tough fibers of the agave plant, is a natural rope solution valued for its moderate strength, durability, and eco-friendly properties. Sisal’s ability to hold knots makes it indispensable in gardening—securing plants, creating trellises, and binding garden structures—as well as in agriculture, packaging, and general utility tasks. Its natural appearance and biodegradability make it a popular choice for landscaping, crafts, and pet toys.

Manila rope, derived from abaca leaf fibers, is the gold standard among natural fiber ropes. It is distinguished by its strength, low stretch, resistance to sunlight, and ability to withstand saltwater, making it the rope of choice for marine, construction, and theatrical rigging. Manila rope remains a preferred material in docks, playgrounds, fencing, and decorative projects where both performance and aesthetics are valued. Find manila rope suppliers for your next outdoor or marine installation.

Cotton rope excels in applications where softness, flexibility, and a gentle touch are required. While not as strong as synthetic or other natural fiber ropes, cotton rope’s ease of handling makes it ideal for crafts, macramé, pet leashes, stage rigging, and event décor. Its natural, hypoallergenic qualities are also beneficial for use in children’s toys and animal handling.

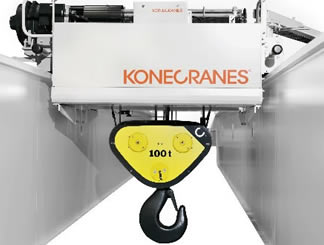

Wire rope is engineered from high-strength steel or other metal alloys and is used wherever exceptional load-bearing capacity and durability are required. Typical applications include crane cables, elevator hoists, suspension bridges, winches, and heavy-duty rigging. Wire ropes are available in a variety of constructions—such as 6×19, 6×37, or 7×19—each balancing flexibility, abrasion resistance, and strength for different industrial needs. For reference, only ropes with a diameter of at least ⅜ inch are classified as wire rope; smaller diameters are considered cord or cable. It is critical to select wire rope that meets industry weight-bearing and safety standards.

Twine, or rope twine, is a slender, twisted rope typically made from linen, cotton, or synthetic fibers. Its lightweight and flexible nature make it ideal for household, office, and culinary tasks—such as tying parcels, creating clotheslines, or securing food. Twine is also extensively used in sports equipment like basketball nets and as garden ties, exemplifying its versatility and everyday value.

Marine rope is specifically engineered for harsh aquatic environments, especially saltwater. Essential for boating, docking, anchoring, and pontooning, marine rope must resist rot, mildew, UV degradation, and abrasion. Commonly made from nylon, polyester, or specialty blends, marine ropes are trusted for their reliability during critical marine operations, from mooring luxury yachts to securing commercial fishing vessels. Research marine rope manufacturers if you need high-performance lines for watercraft or docks.

Elastic cord (or bungee cord) is a flexible, stretchable solution designed to extend up to 125% or more of its original length. Its rubber core delivers high elasticity, while an outer braided sheath—made from cotton, nylon, or plastic—protects against wear and environmental factors. Elastic cords are vital in applications demanding secure yet flexible fastening, such as securing cargo, sports gear, banners, tarps, and luggage. Their adaptability also makes them popular in outdoor recreation, fitness, and automotive industries.

Stair rope is a specialized product designed for bannister and handrail applications, balancing safety and visual appeal. When installed as a handrail, stair rope offers support and comfort, especially on steep or narrow staircases. Stair rope can also enhance interior design, especially when paired with decorative rope brackets or rope lights. For modern installations, metallic cable railing (a type of stair rope) provides a sleek, contemporary look while maintaining strength and safety. Whether your priority is function, aesthetics, or both, stair rope can be tailored to suit residential, commercial, and hospitality environments.

Additional Rope Types and Specialty Applications

Beyond the common types listed above, the rope industry produces numerous specialty products for unique use cases:

- Climbing ropes: Dynamic ropes for rock climbing and mountaineering are built for energy absorption and fall protection, while static ropes excel in caving, rescue, and hauling applications where minimal stretch is crucial.

- Arborist ropes: Designed for tree work, offering high strength, abrasion resistance, and flexibility for climbing, rigging, and lowering limbs.

- Utility rope: General-purpose ropes for camping, hiking, tying down loads, or emergency preparedness kits.

- Paracord (parachute cord): Lightweight, strong, and highly versatile, used in survival gear, outdoor activities, and crafting.

- Theatrical and stage rigging rope: Black-finished ropes for fly systems and curtain controls, designed to blend into stage environments.

Do you need help choosing the right rope for your unique needs? Request a quote.

Rope Accessories

Rope accessories play a critical role in maximizing the safety, usability, and lifespan of your rope. Common rope accessories include:

- Rope clips, clamps, and grips: Used to secure rope ends, prevent fraying, and create reliable terminations. Available in styles for wire rope, webbing, or synthetic cordage.

- Carabiners: Essential connectors in climbing, rigging, and rescue operations. Carabiners come in various shapes, locking mechanisms, and load ratings to suit different safety-critical tasks.

- Ascenders and descenders: Mechanical devices for safely moving up or down ropes, crucial for vertical rescue, caving, and industrial access.

- Prusik loops and friction knots: Enable self-locking and controlled movement on ropes, widely used in rescue, climbing, and tree care.

- Pulleys: Provide mechanical advantage for hauling, lifting, or rescue operations; available in single, double, or specialty designs.

- Rope storage bags and organizers: Protect ropes from dirt, moisture, and UV while keeping them neatly coiled and ready for deployment. Essential for climbers, arborists, and rescue teams.

- Protective sleeves and guards: Shield rope from abrasion and sharp edges in high-wear environments.

When purchasing accessories, prioritize quality and compatibility—mismatched or substandard gear can compromise safety and performance. Trusted brands and specialty retailers offer the most reliable products for professional and recreational users alike.

Proper Rope Care

Extending the lifespan and ensuring the safety of your ropes depends on diligent care and maintenance practices. Here are essential tips for rope care and management:

- Use within specifications: Always respect the manufacturer’s load ratings, temperature limits, and application guidelines. Overloading or using the wrong rope type can cause premature failure and pose safety risks.

- Store properly: Keep ropes in a cool, dry, and dark place, away from direct sunlight and moisture. Use rope bags or hangers to prevent kinking and tangling.

- Inspect regularly: Before each use, check for wear, cuts, abrasion, broken strands, chemical damage, or discoloration. Damaged sections should be repaired or removed; replace the rope if integrity is compromised.

- Clean as needed: Wash dirty ropes with mild soap and water, avoiding harsh chemicals. Dry completely before storage to prevent mildew or rot.

- Repair minor damage: Trim or melt frayed ends to prevent further unraveling. For more serious damage, consult supplier recommendations or replace the rope.

- Retire aged or compromised ropes: Even well-cared-for ropes have a finite lifespan. Follow manufacturer guidelines for retirement based on age, use frequency, and exposure.

Industry Standards for Rope

Adherence to rigorous industry standards is critical for ensuring the safety and performance of ropes in high-stakes environments. In the United States, several organizations develop and enforce standards for rope manufacturing, testing, and use:

- OSHA (Occupational Safety and Health Administration): Regulates workplace safety, including rope requirements for fall protection, rigging, and rescue operations.

- NFPA (National Fire Protection Association): Sets specialized standards for life safety rope used in firefighting, technical rescue, and emergency services (e.g., NFPA 1983).

- ANSI (American National Standards Institute): Publishes consensus standards for rope performance and use in construction, arboriculture, and other fields.

- ASTM International: Establishes testing protocols and specifications for rope materials, construction, and performance.

Rope standards typically address strength, elongation, abrasion resistance, chemical compatibility, and labeling. For example, dynamic climbing ropes must meet specifications for elongation and impact force, while static ropes must maintain minimal stretch and robust load capacity. Life safety ropes and rescue ropes undergo rigorous third-party testing and certification.

Failure to comply with relevant standards can lead to severe consequences, including injury or death for users, legal liability for employers and manufacturers, and costly fines for regulatory non-compliance. Conversely, using certified ropes instills confidence, reduces risk, and demonstrates a commitment to quality and safety. Standards also drive innovation, encouraging manufacturers to develop improved materials, constructions, and technologies to meet evolving industry needs.

Finding the Right Rope Supplier

Choosing a rope supplier is a crucial decision—especially for applications where quality, safety, and performance are non-negotiable. To ensure you receive the best rope for your needs, follow these best practices:

- Define your requirements: Identify the intended use, required strength, stretch characteristics, environmental exposure (e.g., UV, chemicals, water), and any relevant industry standards or certifications.

- Establish your budget and timeline: Consider your volume needs, delivery deadlines, and total project cost.

- Research reputable suppliers: Explore our curated rope supplier directory for manufacturers and distributors with proven expertise in your application area.

- Request quotes and samples: Contact three or four suppliers, provide your specifications, and compare their product offerings, pricing, and lead times.

- Evaluate support and service: Assess each supplier’s technical support, warranty, return policies, and customer reviews to ensure a reliable partnership.

Whether you need industrial bulk rope, specialty marine lines, safety rope, or custom assemblies, partnering with an experienced supplier guarantees you receive certified, high-quality rope tailored to your exact requirements. Ready to get started? Contact a rope supplier today for expert assistance.

What materials are commonly used to make rope?

Rope is made from a variety of materials. Common synthetic fibers include nylon, polyester, polyethylene, and polypropylene, which are valued for their strength and resistance to the elements. Natural fiber ropes are made from sisal, jute, manila, linen, coir, and cotton. For applications needing even greater strength, wire rope is made from metals such as stainless steel or galvanized steel.

How is rope constructed, and what are the main types of rope construction?

The two main rope construction methods are twisting (laid rope) and braiding. Twisted rope is formed by coiling fibers or strands together, while braided rope is woven in intricate patterns for higher strength and flexibility. Specialty types such as double braided, solid braid, and hollow diamond braid provide different performance characteristics. Wire rope construction involves twisting multiple strands of metal wire into cables for maximum strength.

What are the most common types of rope and their primary uses?

Common rope types include nylon (for towing and anchor lines), polyester (for marine and outdoor use due to durability), polypropylene and polyethylene (which both float, used in aquatic applications), sisal and manila (natural fibers, popular in marine and landscaping), cotton (for crafts and animal handling), wire rope (for heavy-duty industrial uses), twine (for light tasks), marine rope (for boating and aquatic environments), elastic cord (for securing items), and stair rope (for handrails and decor).

What accessories are recommended for safe and effective rope use?

Rope accessories include rope clips and clamps, carabiners, ascenders and descenders, prusik loops, pulleys, storage bags, and protective sleeves. These items enhance safety, longevity, and usability, especially for activities like climbing, rigging, rescue, and transportation.

How should rope be cared for to extend its lifespan?

Proper rope care includes using it within specified load and environmental ratings, storing it in a cool, dry place away from sunlight and moisture, regularly inspecting for damage, cleaning as needed with mild soap and water, repairing or trimming frayed ends, and retiring ropes that are aged or compromised. Always follow manufacturer guidelines for inspection and retirement.

What industry standards and organizations govern rope quality and safety?

Organizations such as OSHA, NFPA, ANSI, and ASTM International provide regulations and standards for rope manufacturing, testing, and use. Standards address strength, elongation, abrasion resistance, chemical compatibility, and labeling. Using ropes that comply with industry standards is essential for user safety and legal compliance.

How can I select the right rope supplier for my needs?

To choose the right rope supplier, define your project requirements, establish a budget and timeline, research reputable suppliers, request quotes and samples, and evaluate their technical support and service policies. Partnering with an experienced and certified supplier ensures you receive high-quality rope that meets your specific needs.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services