Manila rope is a very durable and flexible rope material, making its use essential in a wide variety of industries. Manila rope is used in fishing, shipping, ranching, construction, architectural, climbing and agricultural environments. Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

At Yale Cordage, we take pride in engineering and manufacturing advanced rope solutions that push the limits of performance, safety, and innovation. Our focus has always been on creating synthetic ropes that outperform traditional fiber and wire rope, offering exceptional strength, flexibility, and longevity across a wide range of demanding applications.

Samson Rope Technologies can supply you with braided rope, nylon rope, sash cord, and rope & cordage for general use. Not only do we provide specific solutions to our customers, but we also follow up with instructions for the use and care of our products.

At Erin Rope Corporation, we take pride in our long-standing expertise in designing and manufacturing high-performance rope solutions that meet the demands of industries across the globe. We specialize in the engineering and production of ropes built to perform under pressure, offering durable, reliable, and precise products that serve a wide range of applications from construction and marine to...

At Cancord Ropes, we take pride in designing and manufacturing high-performance ropes that meet the demanding requirements of modern industries. Our expertise lies in crafting synthetic and blended fiber ropes that deliver exceptional strength, durability, and flexibility for a wide range of applications.

More Manila Rope Suppliers

Manila rope is used in the crafting of handcrafts, bags, carpets, clothing, furniture and landscaping as with decorative fencing due to its visual appeal. More than aesthetics, the natural abaca plant hemp fibers used in the production of this rope are resistant to UV light and water, making it particularly useful in outdoor and sea contexts as does its ability to hold knots firmly.

Manila is fast absorbing and snap resistant, allowing safe use in pulleys and winches. Although it will burn at temperatures greater than 180° F, these ropes will not melt like many synthetics will. This heat resistance adds to the rope's mechanical capabilities. While it does not stretch, manila ropes may shrink when wet. When a wet rope dries it can become stiff and tight. For this reason many new ropes are immersed in water and dried before initial use as shrinkage decreases with each wetting. In some situations, such as nautical knots, pre-wetting is not used as the hardening and tightening of the knot may be desirable.

Manila rope begins with fibers from the abaca plant. This tropical specimen is native to the Philippines, making that country one of the largest manila rope producers. These natural fibers are spun to make yarn that is then braided or twisted to make the rope. Both twisted and braided varieties are popular, though twisted ropes are more susceptible to unraveling. As texture and softness varies among the abaca plant, the origin of a particular rope is important in the grade or rating of manila rope. This system takes into account the strength, manner of cleaning and color of the Manila hemp as well as fiber length.

The natural qualities of these fibers are often enhanced with treatments such as copper napthenate, tar or tallow to minimize loss of strength due to fungi, mildew and rot in addition to adding protection against chaffing in high stress situations. While abaca fibers will resist water and sunlight, they are not resistant to chemical corrosion. The available treatments can provide this feature and prolong the working life of manila rope. While grade and treatment are important, further considerations include strength lifts, abrasion resistance, flexibility, lay and cord size. Rope suppliers may provide insight into the rope requirements for a specific task.

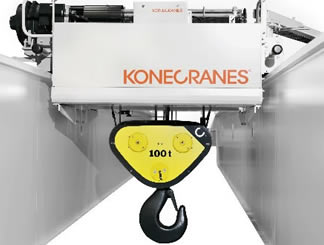

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services