Because they are placed under so much strain, even light duty tow ropes need to be very strong and durable to prevent them from snapping when pulling a load.

Strong hooks on either end of the rope are used to attach the rope to a secure point on the vehicle and the object being pulled, and anyone using the rope needs to be careful that they don’t fix the hook to a weak point that could be separated from the vehicle when force is applied to it. Towing ropes are useful in industries like shipping, vehicle salvage, fishing and more.

A towing rope is rated by its breaking strength. Most light duty tow ropes that are made for use with light equipment or small cars have a breaking strength of 2000lbs, which simply means that they can safely tow up to 2000lbs. Extremely heavy duty tow ropes can have a breaking strength of hundreds of thousands of pounds and these can be used for vehicle rescue, heavy industrial equipment towing and marine towing of large container ships.

Features like safety snaps on the hooks, a ratcheting mechanism or a retractable housing for the rope can be added to the tow rope, but most are very basic. Some just have hoops on either end of the rope instead of metal hooks.

Although a variety of materials are used to create towing ropes, the most common choice is a two inch strip of nylon. Because nylon is so strong, if it is thick enough it can be used to form a rope that can bear a very high weight capacity. Nylon is also highly resistant to oil and other chemicals and it will not fray or weaken in the sunlight as other types of ropes tend to do.

The nylon is usually dyed to a color that corresponds with its maximum towing capacity, and its pieces of long extruded mono-filament are usually braided or twisted intricately together to create a strong rope. Polypropylene and polyester are also used in marine towing applications.

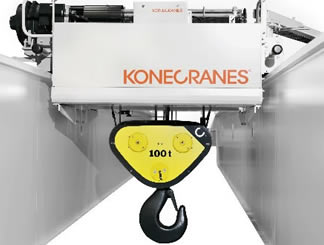

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services